Requirements

- input and output part

- actuator output part: e.g. servo motor, LED

- part that requires a library: e.g. remote control, capacitive touch, servo motor

- >1 library; otherwise, >1 sensor input and 1+ actuator output

- if using analogRead(), code that calibrates sensor readings

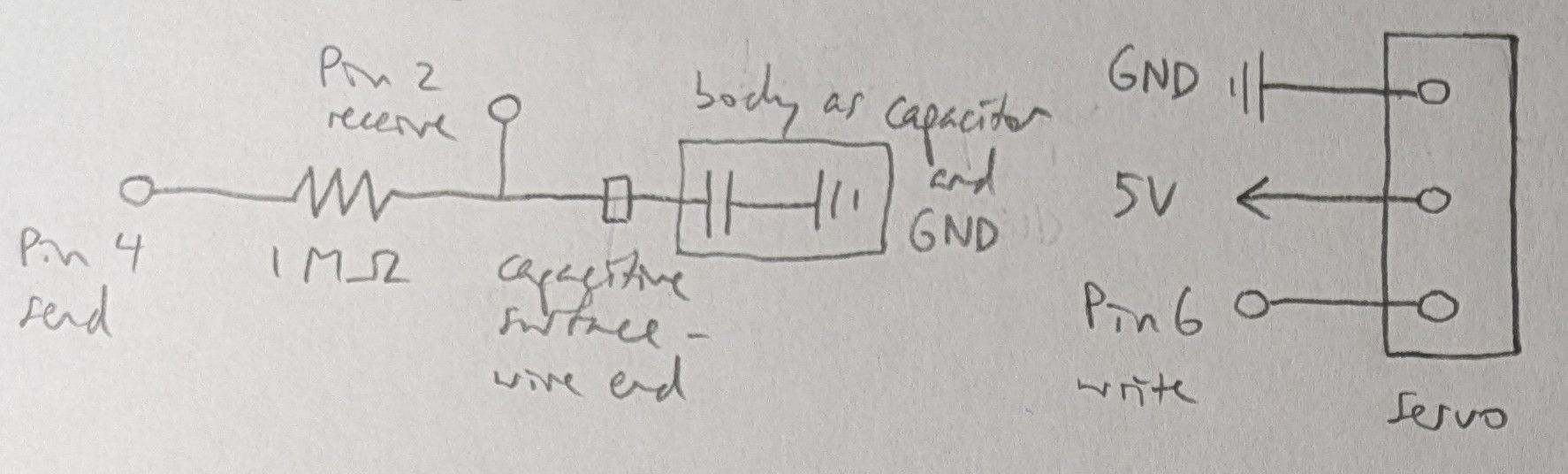

Schematic

The capacitive surface for the sensor is the end of a wire.

The capacitor and ground for the sensor are the body of the person interacting with the circuit.

Resistance of 1 MOhm was chosen for the capacitive sensor based on the library guidelines for resistor choice to activate on touch contact.

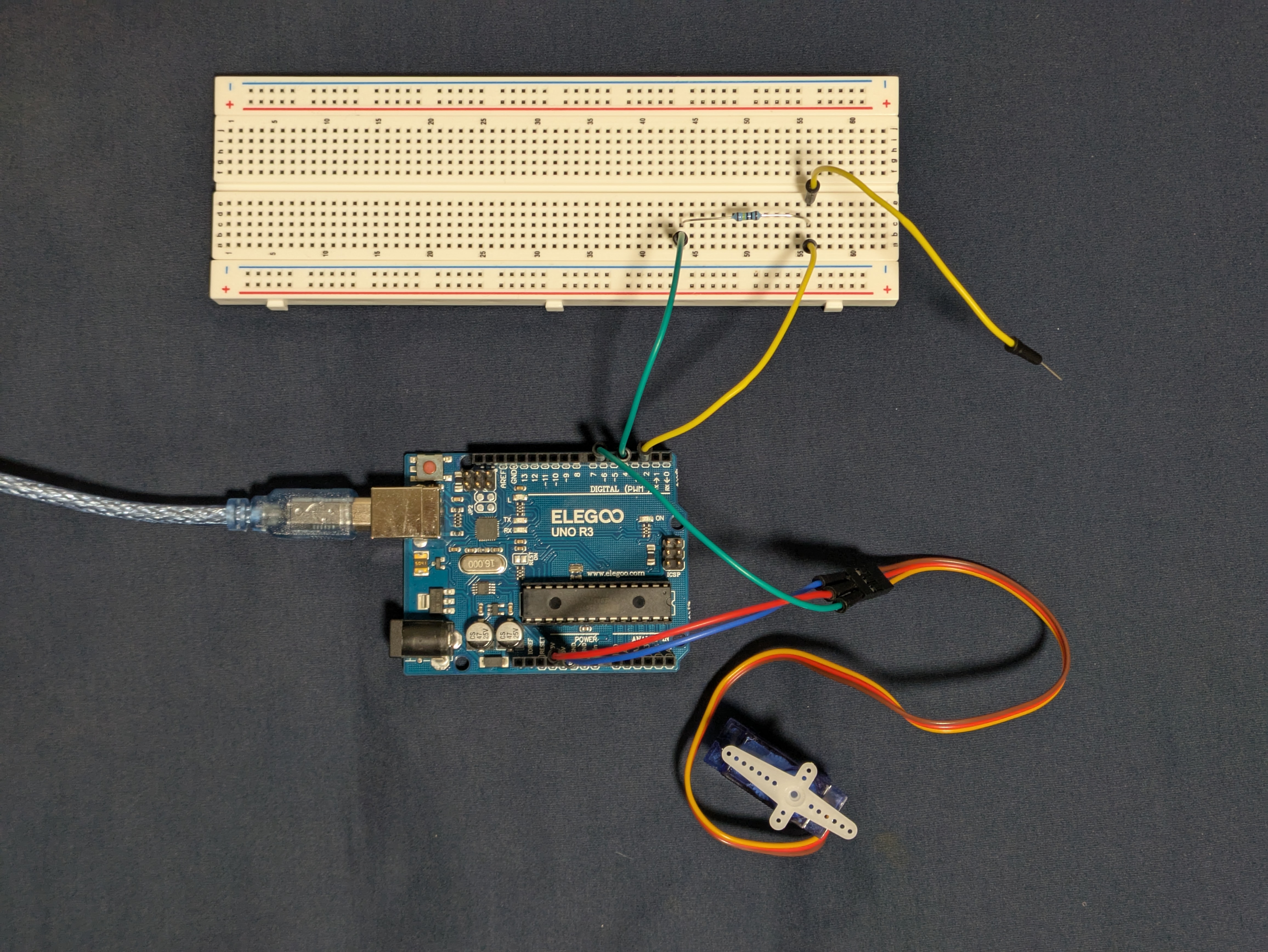

Circuit

Firmware

link to code file

/*

Libraries

Built with Examples/CapacitiveSensor/CapacitiveSensorSketch and Examples/Servo/Knob

The servo motor points right when the capacitor is activated

and left when the capacitor is deactivated.

The servo motor output is attached to pin 6.

The capacitor input is attached to pin 4 for send and pin 2 for receive.

modified 26 Oct 2025

by Heidi Wang

*/

#include

#include

// 1 megaohm resistor between pins 4 & 2,

// pin 2 is sensor pin, add wire, metal capacitive surface

CapacitiveSensor cs_4_2 = CapacitiveSensor(4,2);

// initialize servo object

Servo myServo;

// the number of the write pin for the servo

const int servoPin = 6;

// the threshold for activating the capacitive sensor; change as needed

int threshold = 240;

// the setup function runs one time when the program is started

void setup()

{

// attach servo object to servo pin

myServo.attach(servoPin);

// begin serial communication at 9600 bits/s (baud)

Serial.begin(9600);

}

// the loop function loops indefinitely

void loop()

{

// read in the capacitive sensor value over 30 samples of measurement

long sensorValue = cs_4_2.capacitiveSensor(30);

// print the sensor value

Serial.println(sensorValue);

// rotate the servo depending on whether the sensor value passed the threshold

if (sensorValue > threshold) {

// rotate the servo to the right when the sensor is activated

myServo.write(180);

} else {

// rotate the servo to the left when the sensor is deactivated

myServo.write(0);

}

// delay 15ms between reads

delay(15);

}

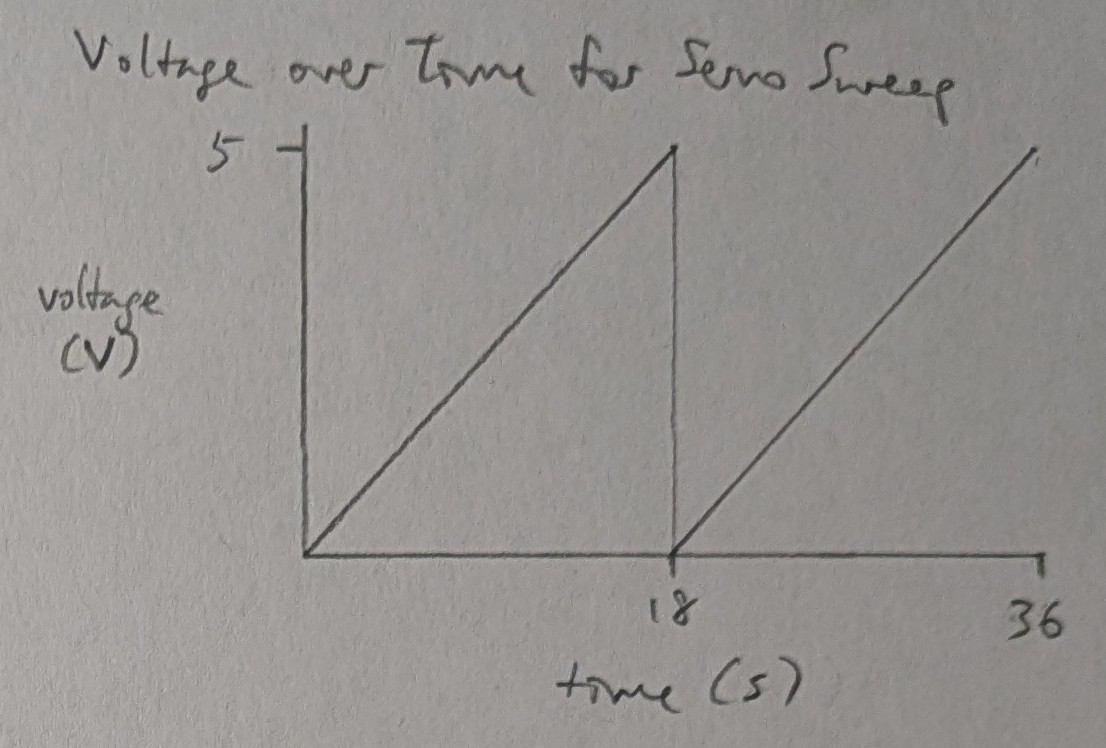

Operation

Questions

-

-

We can address erroneous readings by only changing the output if the reading was not an error code.

CapacitiveSensor error codes are -1 or -2, and >= 0 otherwise.

// read in the capacitive sensor value over 30 samples of measurement long sensorValue // do not change the output if the read value was an error code if (sensorValue >= 0) { // rotate the servo depending on whether the sensor value passed the threshold if {} else {} } -

If the measurement is noisy and deviates from the true measurement by +/- 10%, we can take multiple readings and average them before each adjustment to get a smoother output.

// average 5 readings of the capacitive sensor value over 30 samples of measurement long sensorValue = 0; for (int i = 0; i < 5; i++) { sensorValue = (sensorValue*i + cs_4_2.capacitiveSensor(30))/(i+1); } -

No AI use.